A Guide To Fat Quarters

So you see a new fabric collection and you’re like…

I LOVE IT

…but how much of it do I need? Can I afford them all? I can’t possibly choose!

Oh yeah, we totally get you.

This is why we offer fat quarter bundles so you can love it, make it & keep it!

Watch our video then check out the written guide below for the full fat-quarter lowdown!

What is a fat quarter?

You might have seen FQ on a tutorial and you’re like… what?!

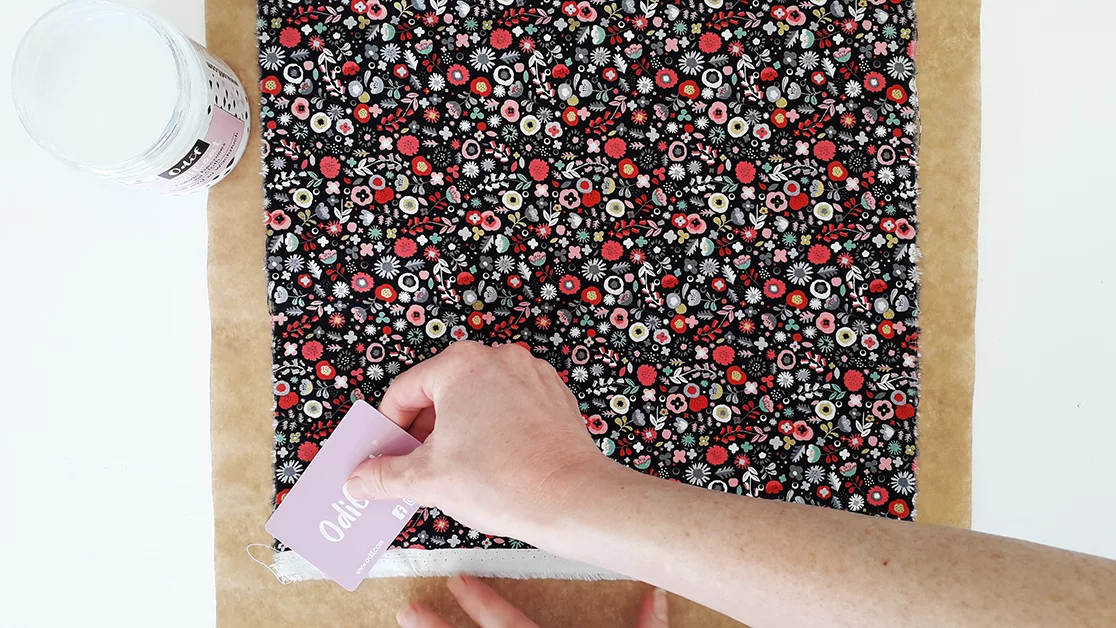

FQ stands for fat quarter, which is a piece of pre-cut fabric that is made by cutting half a metre of the full fabric width from the bolt and then cut in half vertically, hence ‘quarters’. Most quilting fabrics are 44”/110cm wide, which makes fat quarters around 50cm x 55cm.

A fat quarter cut is a square shape which means you’re getting more scope to make wider things out of it, even though it’s technically the same surface area.

You may find that some fabrics have a wider width, such as our PUL and Bamboo Velour. We sell this by the fat quarter, however the width can be up to 150cm, so you would get a very generous amount of fabric!

You may find that some fabrics have a wider width, such as our PUL and Bamboo Velour. We sell this by the fat quarter, however the width can be up to 150cm, so you would get a very generous amount of fabric!

Boring Legal Bit: If you follow any tutorial or guidance found in this post, or on this blog, you agree to be bound by our disclaimer which can be viewed here

Where can I buy fat quarters?

Right here at Plush Addict! We sell quilting collections in fat quarter bundles and you can buy any of our fabrics as a fat quarter, as they are cut bespoke for you when you order. We even have a colour matching service, just pop in the order notes which fabrics you’d like us to colour match and we’ll check for you.

Did you learn a lot from this blog? We’d love to hear from you in the comments!

Never miss a guide or tutorial

Click to join our mailing list!

Pin this for later!

Never miss a guide or tutorial

Click to join our mailing list!