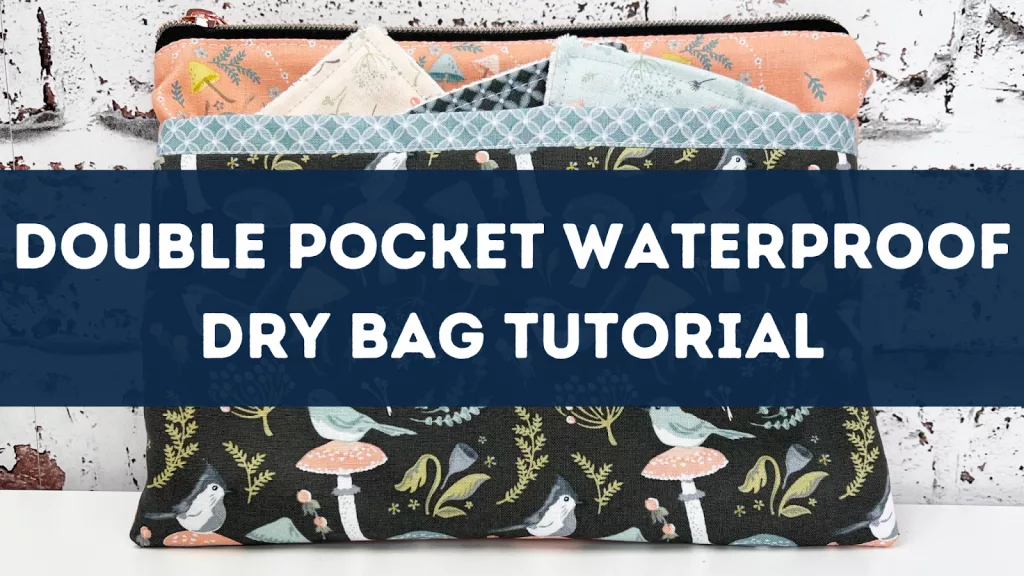

Tutorial: Sew a Cot Bed Duvet Cover

Free DIY Toddler/Cot Bed Duvet Cover Tutorial

Moving up into a ‘big bed’ is a significant milestone for many a toddler, getting them to stay there and sleep can be a different matter… Maybe their very own special bedding set will give them the incentive to stay put, allowing them (and you!) to have a good nights’ sleep! Therefore, we have prepared this Sew a Cot Bed Duvet Cover tutorial to help you get started.

Pin me for later!

Boring Legal Bit: If you follow any tutorial or guidance found in this post, or on this blog, you agree to be bound by our disclaimer which can be viewed here

This cot bed duvet cover tutorial has been designed to make the very best use of the Silk Road Border Print fabric. If you’re not use what a border print is then check out our guide here

You will learn:

· How to form a grown on placket

· How to add a sewn on placket

· How to sew a button hole

· How to use Kam pliers

· How to sew a French seam

These measurements will fit a cot bed duvet size 150 x 120cm and a toddler pillow size 60 x 40cm

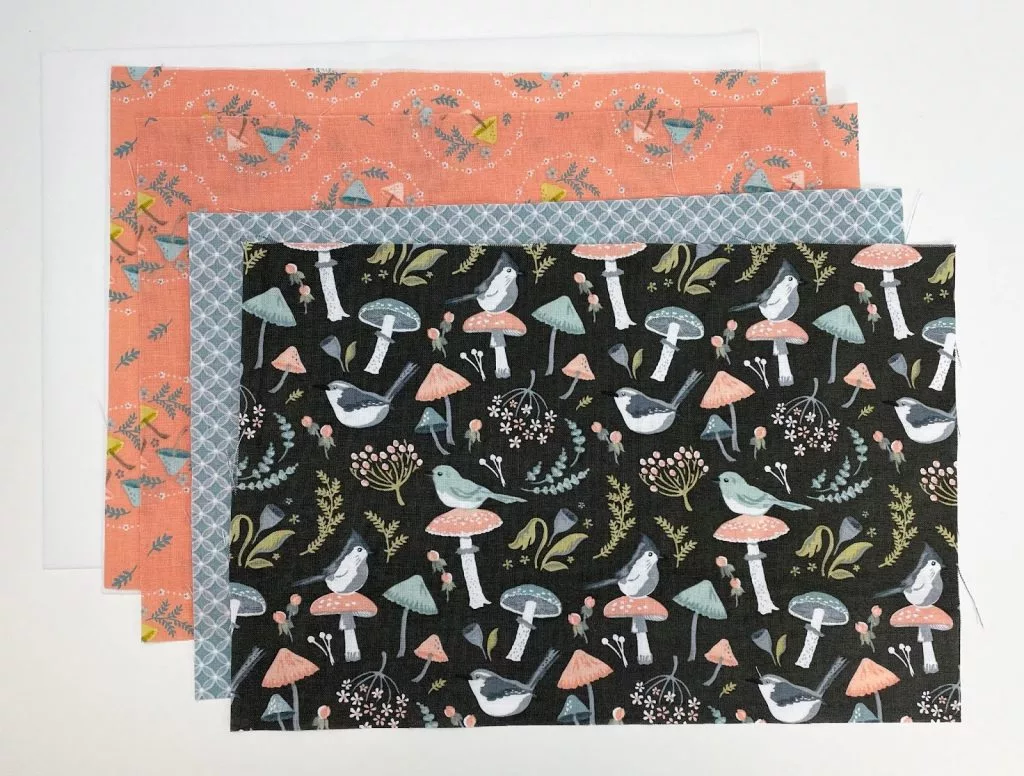

You will need:

- 2.1m 110cm wide Cotton border print (Fabric A)

- 1.5m 110cm wide Contrast print cotton fabric (Fabric B)

- 1.5m 110cm wide Solid colour cotton fabric (Fabric C)

- 1.25m Lightweight fusible woven interlining (or you can piece interfacing scraps if you don’t have 1.25m in one strip – Grab 10% off Woven Interlining with WOVEN10)

- Thread

- 7 KAM snaps and pliers OR 7 Buttons

Here we used*

- Dashwood Silk Roads collection – Border print

- Dashwood Silk Roads collection – Paisley yellow

- Robert Kaufman Kona Nautical

- Fusible woven interlining (a lighter weight would give a softer finish)

- Thread

- Buttons

- KAM snaps

- KAM pliers

*Toddler duvet size 150 x 120cm, Toddler pillow size 60 x 40cm

A Note On Sewing French Seams

French seams are most commonly used for fine fabrics, we are using them here for a few reasons:

- The seam is sewn twice, making the finished item more durable.

- Raw edges are enclosed in the finished seam, to give a neat finish.

- This gives an opportunity to practice French seams with more forgiving fabrics.

Please note: On fine fabrics the 1st seam sewn allowance is trimmed as a wider seam allowance is sometimes necessary for this step. As cotton is being used here, a 5mm seam can be normally be sewn on a domestic machine without the fabric being ‘chewed’. The finished seams here will not be visible as per sheer fabrics, therefore a slightly bulkier finish does not present any aesthetic issues. The final seam on fine fabrics would be narrower, but in the interest of gaining insight into the technique, the seam allowances are not being trimmed following the 1st sew, unless you wish to.

Important notes:

1.5cm seam allowance throughout, unless directed

For steps using machine sewing, straight stitch, backstitching at the start & end using stitch length 2.5 unless otherwise stated

Prepare your fabrics as per manufacturers care advice

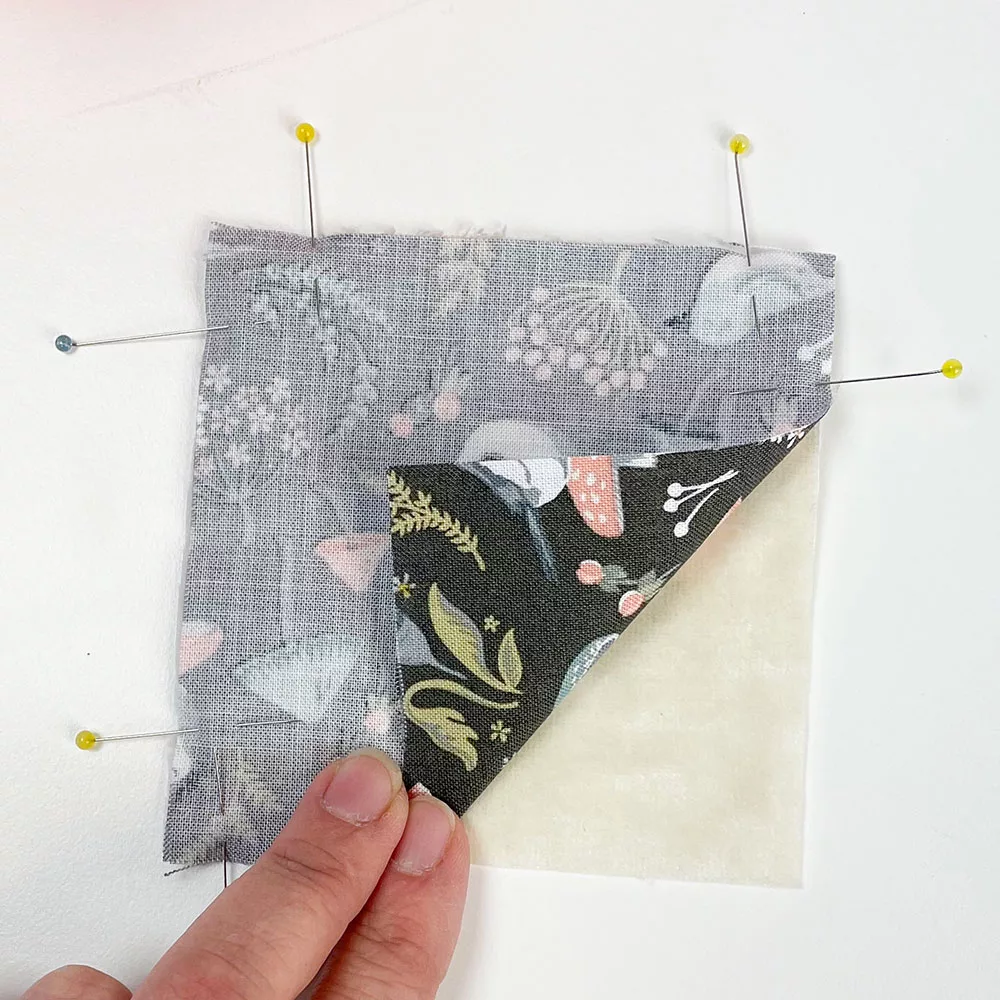

How to sew a DIY Toddler duvet cover

In this part of the cot bed duvet cover tutorial, let us go through the steps in sewing a duvet cover for your toddler.

1. Cut out the fabrics out as follows:

Border print Fabric A:

- 110 x 123cm Duvet front piece

- 78.5 x 43cm Pillow front

- 63.5 x 43cm Pillow back

Contrast print Fabric B:

- 43 x 123cm Duvet front piece

- 66.5 x 123cm Duvet back piece

Block colour fabric Fabric C:

- 93 x 123cm Duvet back piece

- 8 x 123cm placket

Interfacing:

- 8 x 123cm Sewn on placket

- 5 x 123cm Grown on placket

Make the plackets

1.How to sew a grown on placket

2. Apply the 5cm wide strip of woven interlining to the back of the bottom edge on the contrast back duvet piece

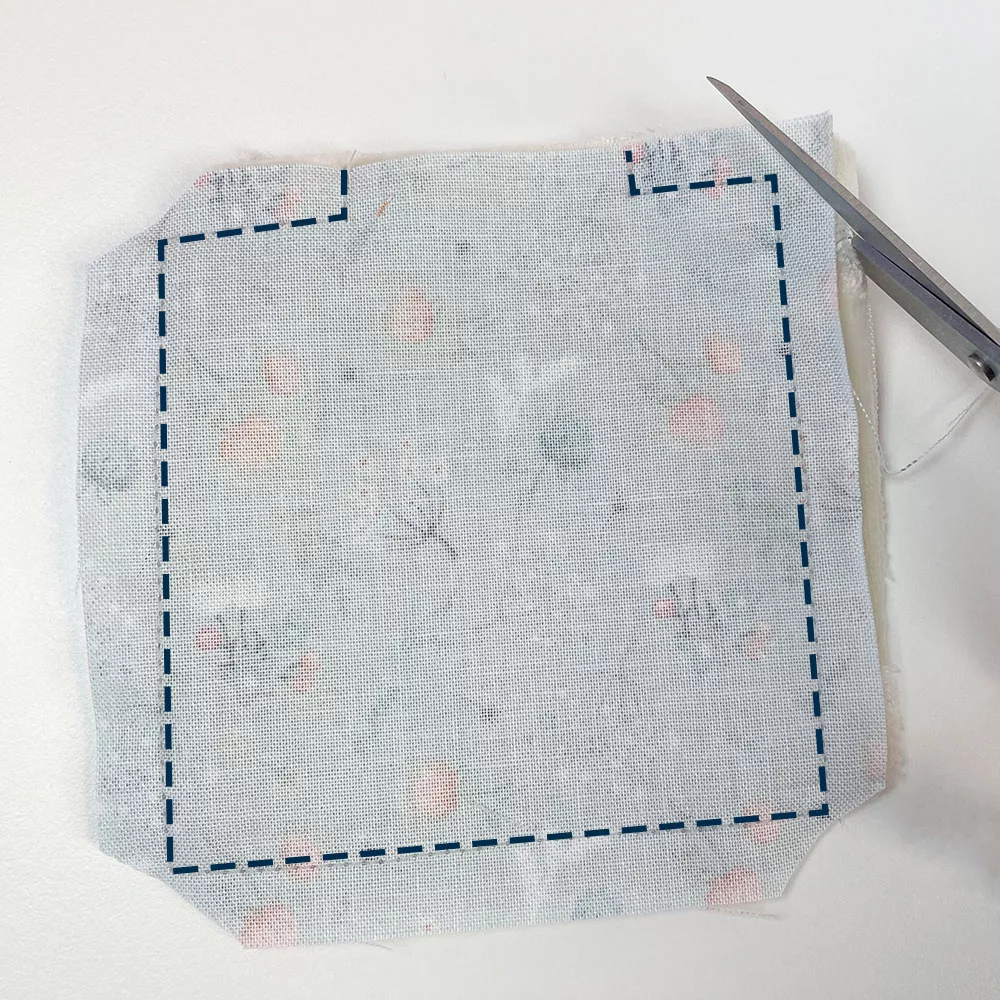

3. Fold over and press the bottom 5cm of the back duvet piece

4. Tuck the raw edge under to meet the crease and press again to form the placket

5. Measure and mark 20cm from each end of the placket

6. Starting at one mark top stitch along each edge of the placket, 3m from the crease and stop when the other mark is reached

How to sew a sewn on placket

7. Apply the 8cm wide interlining to the placket

8. Fold the placket in half and press

9. On one side of the placket only fold over 1.5cm and press

10. Pin the right side of the unfolded edge of the placket to the wrong side of the bottom edge of the border print duvet front piece and sew

11. Press the seam open with the seam allowance pressed toward the placket

12. Pin along the placket on the right side of the duvet front piece

13. Measure and mark 20cm from each end of the placket

14. Starting at one mark top stitch along each edge of the placket, 3m from the crease and stop when the other mark is reached

Assemble the front panel sewing French seams

15. Pin the wrong side top edge of the border print duvet front piece to the wrong side bottom edge of the contrast duvet front piece

16. Sew with a 5mm seam allowance

17. Press the seam open with the seam allowances to one side, trim any loose threads

18. Fold along the seam to bring the 2 fabrics right sides together and press

19. Pin then sew with a 1cm seam allowance

20. Press the seam allowance toward the border print fabric

Assemble the back panel sewing French seams

21. Pin the wrong side top edge of the contrast duvet back piece to the wrong side bottom edge of the solid colour duvet back piece

22. As per steps 16. To 19; Begin the French seam and sew with a 5mm seam allowance

23. Press the seam open with the seam allowances to one side, trim any loose threads

24. Fold along the seam to bring the 2 fabrics right sides together and press

25. Pin then sew with a 1cm seam allowance

26. Press the seam allowance toward the contrast fabric

Join the Placket ends

27. Align the front and back duvet panels right sides together

28. Clip the 2 plackets together

29. One end at a time, sew along one side of the plackets 3mm from the edge, along the marked line (from step 5 & 11), then back along the other edge of the plackets. To reinforce the marked line, backstitch along it before continuing

30. Fold the front and back duvet panels along the inner edge of the placket to bring the wrong sides together with the placket tucked in along the bottom edge. Press along the placket edges

Assemble the duvet cover using French seams

31. Smooth out the duvet front and back panels wrong sides together and pin along the top edge

32. Sew a French seam as per steps 16. to 19

33. Turn the duvet cover right side out and smooth out the front and back fabrics

34. Pin the sides together, wrong sides facing.

35. Sew French seams in the 2 sides as per steps 16. To 19.

Please note: After sewing and pressing the first part of the seam turn the 2 corners of the top seam allowance to overlap the same side at each end and sew over the ends with the 1cm seam. For the placket end; trim the placket seam allowance as close to the seamline as possible and turn the plackets to the same side each end, then sew over the ends with the 1cm seam.

Prepare to add the fastenings

36. Make 7 marks at the following points on the inside of the front and back plackets:

- The centre of the placket

- 3 marks at 10cm intervals to each side of the centre

37. Follow either the KAM snap or button hole directions to add the placket fastenings:

How to attach KAM snaps

38. Add the Kam snaps at the marked positions: Use female snaps on one side of the opening and male snaps on the other with the smooth sides on the inside of the placket.

a) At the centre of the mark use an awl to make a hole through the placket only.

b) Thread the snap backing piece through from the underside of the placket.

c) Clip the applicable snap piece onto the top side.

d) Line the snap back piece up in the plier base.

e) Position the pliers on a solid surface and press firmly (lean into the pliers for added force) until the snap is fixed in place.

f) Repeat for all snaps, if you’d like to see a video on KAM snaps, click here.

39. Sew the buttonholes and attach the buttons, for a handy guide on this check out our ‘How to Sew a Buttonhole’ blog here or our video guide here.

How to sew an envelope pillow

Prepare the pillow front

40. With the pillow front right side down fold over and press 2cm of the short edge on the left

41. Tuck under the raw edges to meet the crease and press again to form a hem

42. Sew along the innermost crease, 2mm from the crease edge

Prepare the pillow back

43. With the pillow back right side down fold over and press 2cm of the short edge on the right.

44. Tuck under the raw edges to meet the crease and press again to form a hem

45. Sew along the innermost crease, 2mm from the crease edge

Form the envelope

46. Line up the short raw edges of the pillow front and pillow back wrong sides together and pin

47. Sew a French seam as per steps 16. to 19.

48. Fold the pillow along the sewn seam bringing the wrong sides together

49. Pin along the 2 sides of the pillow stopping 2 thirds of the way up

50. Fold the excess fabric down in between the 2 fabric layers and smooth it out. The fold needs to align with the top of the pillow back hemline

51. Finish pinning the 2 sides of the pillow

52. Sew along each side with a 5mm seam allowance.

53. Press the seams open with the seam allowances to one side, trim any loose threads.

54. Turn the pillow case, then turn the envelope flap right side down.

55. Turn 2 ends of the sewn seam allowance to the same side

56. Pin then sew each side with a 1cm seam allowance

57. Turn the pillow out the right way and press.

And you’re finished, well done!

Would you love a mattress protector to match? Check out this tutorial!

Pin this for later!

Let us know how you get along in the comments below!

Follow Plush Addict on social media and keep an eye out for more tutorials. Please tag us @PlushAddict on your fave social media channel… we love to see your makes!