A Beginner’s Guide To Dressmaking Patterns

Are you intimidated by patterns? Not sure how to read a sewing pattern?

Confused by the back of the envelope? Not sure what the symbols mean?

We’ve got you covered!

Grab a cuppa, read on & let us demystify how to read a sewing pattern!

How To Read A Sewing Pattern

To the uninitiated, a first glance at a sewing pattern can be daunting. Have a read through our top tips & feel more confident having a go!

How to read the back of a sewing pattern envelope

The back of the pattern envelope should be your first port of call.

It contains lots of essential information you will need to make your garment.

You’ll find fabric suggestions that will suit the pattern style, the amount of fabric you will need & all the required notions such as zips & buttons.

Inside the pattern envelope

Inside you’ll find various sheets of paper – these will you be your pattern pieces, your sewing instructions & also the pattern layout information to help you cut out your pattern pieces correctly.

Tips On Choosing Fabric

Choose a fabric that is mentioned in the “suggested fabrics” section on the outside of the pattern envelope.

If your chosen fabric has a pattern “direction” make sure you place your pattern pieces the correct way up or your fabric motif will appear upside down on your garment!

A Tip For Stripes – Make sure the stripes run the way you want them to in your finished garment when laying out your pattern pieces.

Motif Sizes – Ensure your fabric has appropriately sized motifs for your garment. For example, a child’s dress might look strange in a large statement floral fabric.

ALWAYS Pre-wash Your Fabric – Some fabrics will shrink. It is better to launder your fabrics first to save tears later! Wash your fabric how you intend to wash the finished garment.

Understand Sewing Pattern Symbols

Understanding Sewing Pattern Symbols

Understanding Sewing Pattern Symbols

Pattern Piece Layout

Your pattern will have a diagram similar to this which is showing you how to lay out your pattern pieces on your fabric.

Following this diagram will usually be the most economical layout when cutting your fabric.

There will usually be two layout guides – one for 44″ wide fabric & another for 60″ wide fabric.

Follow the appropriate layout for your chosen fabric’s width. There may also be a layout guide for your interfacing pieces.

Looking more closely at the diagram above you will see that pattern piece (2) needs to be cut twice as it appears twice on the cutting diagram. Once the pattern piece is cut with the right side facing up, the second time it is cut with the pattern piece facing down.

Can you see where this pattern piece is shaded by the dots? This indicates the pattern piece should be laid face down on your fabric. The unshaded pieces indicates your pattern piece is face up.

Pattern piece (1) is placed on the fabric fold – we will end up with 1 pattern piece double the size of the paper pattern piece.

Pattern piece (4) indicates only one thickness of fabric – can you see how the selvedges aren’t aligned? Again – pattern piece (4) is cut twice – once with the pattern piece is right side up and then once with the pattern piece right side down – remember the dots?

Never miss another tutorial or guide…

Stay up to date with the latest by signing up to our newsletter!

Click to join our mailing list!

https://www.instagram.com/plushaddict/

How To Use Odicoat Fabric Coating Gel

You will learn how to use Odicoat fabric coating gel in this tutorial. In addition, we will be guiding you on its various benefits and uses.

Ever found the perfect fabric with the wrong composition for your project? If the missing element was waterproofing then we have discovered a brilliant solution; Odicoat. This clever gel gives fabrics a waterproof coating that is machine washable.

This isn’t the only use for this clever product, Odicoat also works as a fabric glue; Fabric can be applied to objects for decorative purposes.

A product guide for beginners

There are a few ways to waterproof fabrics, depending on the finish you are looking for.

Below you’ll find both a video tutorial on how to use Odicoat fabric coating gel as well as a more detailed photo tutorial so you can learn all about Odicoat! We hope you this post helpful.. Do let us know in the comments.

You’ll also find a cheeky discount code for your next Odicoat purchase at the end of the tutorial…

Boring Legal Bit: If you follow any tutorial or guidance found in this post, or on this blog, you agree to be bound by our disclaimer which can be viewed here

Why use Odicoat?

Benefits of Odicoat

- Odicoat leaves fabric with a lightly rubberised feel; think of the finish (3 coats) as a more pliable oilcloth

- Once application is complete the fabric is machine washable up to 30 degrees

- Coated fabric is easier to cut, more durable and less prone to fraying

- The finished fabric can be sewn, as you would PUL or oilcloth fabrics. Check out our full Waterproof Fabric Guide for more info

- Waterproof fabrics offer greater stain resistance

- Odicoat is water based, BPA free and acid free

- Treated fabrics have a little more structure

Uses for Odicoat

- Aprons

- Tablecloths

- Placemats

- Wash bags

- Make up bags

- Embellishing decorative items

- Outdoor cushions

Additional information

- A single coat will give a matt finish, 2 or 3 coats will give a gloss finish:

1 coat – the fabric is protected, water repellent, with a matt finish

2 coats – the fabric is coated, with a gloss finish

3 coats – the fabric is waterproofed, with a high gloss finish

- Fabrics coated with Odicoat should only be washed at 30o

- Prepare your fabrics as per manufacturers care advice before applying Odicoat

- Use clips or pin within the seam allowance – pin holes will remain visible

- Treated fabrics will have less drape

- We recommend testing the suitability of Odicoat on spare pieces of the project fabric/ hidden area of an object before proceeding

- Not suitable for thick velvet, suede or embossed fabrics

- Foods must not make direct contact with Odicoat treated items

- Odicoat is made in France by Odif

Disclaimer

- Odicoat should only be used for it’s intended purpose

- Follow the usage instructions

- Always wash hands after use

- Not for consumption

- Keep out of the reach of children

- Odif cannot be responsible for dangerous storage conditions or misuse

How to apply Odicoat

You will need:

- Cotton fabric

- Odicoat

Here we used:

- A quilting cotton

- 3 coats of Odicoat

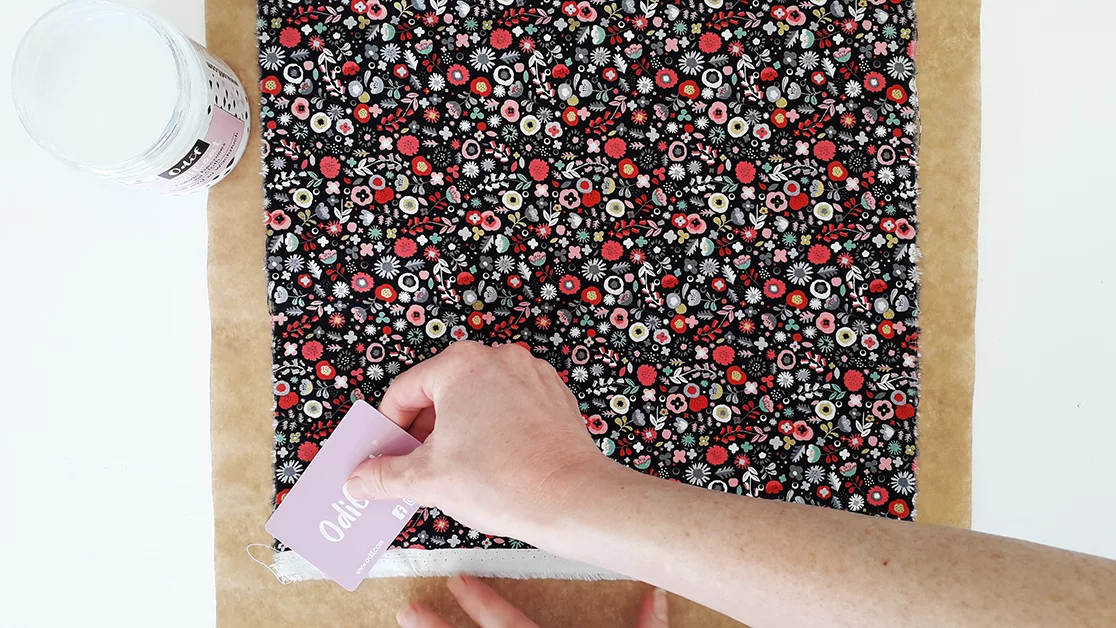

1. Before cutting fabrics to size, in case of shrinkage, apply the Odicoat to the right side of the fabric: Place your fabric right side up on a protected surface (greaseproof or plastic sheeting are ideal)

2. Using the card provided spread a thin layer of Odicoat onto the fabric; start from one corner and work outwards. Go back over the fabric with the card spreading out any thick patches/ streaks. Avoid moving the fabric until it is dry to prevent Odicoat getting onto the wrong side

3. Wait until the Odicoat is touch dry (20 to 30 minutes), cover with greaseproof and dry iron, heat setting 1/satin

4. Apply a second coat, as per steps 2. And 3. A third coat can be applied if required

5. Allow 24 hours for the Odicoat to cure fully then carefully peel the fabric off

How to use Odicoat as a glue

Odicoat can be used to stick fabric to wood, cardboard, metal, glass, ceramic, pottery, Styrofoam and stone. Once applied the Odicoat will give a water-resistant, satin finish:

1. Apply Odicoat to the back of the fabric being adhered with a flat brush

2. Position the fabric on the chosen surface

3. Apply another coat of Odicoat over the fabric

4. Wait 1 hour

5. Apply a second coat (optional)

6. Wait 24 hours

Check out our video below!

And you’re finished, well done!

Pin this for later!

We hope you found this tutorial useful!

How To Sew a Buttonhole Tutorial

How To Sew a Buttonhole

Sewing a buttonhole might look a little intimidating at first, but with this handy step by step guide, you will learn how to sew a buttonhole. As a result, you’ll be sewing on buttons with ease!

We’ve even included some troubleshooting tips…

Don’t miss the video showing you this technique which you can view at the end of the photo tutorial…

Boring Legal Bit: If you follow any tutorial or guidance found in this post, or on this blog, you agree to be bound by our disclaimer which can be viewed here

How to sew a buttonhole

1.. Every sewing machine varies in terms of the settings needed but the basic principles remain the same. Check the machine manual for how to set up the machine.

It will most likely advise the need for a buttonhole foot (not essential but makes it easier to track progress), the stitch selection needed and a tension adjustment (mark the normal tension setting with a sharpie/ take a picture for resetting the machine after)

For irregular shaped buttons; buttons pass through the hole from any direction so a narrower measurement can be used provided the button isn’t excessively long. If a longer measurement is used the button may come undone in use. If in doubt, practice on a scrap of fabric first.

3. Mark the length of the button parallel to the placket edge, central to a placement mark

Button holes allow movement; the direction of the hole is determined by the most likely direction the fastened button needs to move. The foot of a duvet won’t move much, therefore the button holes are positioned for best fit.

4. Extend the button hole line by approx. 2mm top and bottom to allow room for the top and bottom closing bar

5. Prepare the machine to sew a button hole, then wind the hand wheel until the needle is positioned to the inside of the button hole (the right)

6. Position the placket under the presser foot. Line up the front of a button hole marking under the needle. Move the hand wheel until the needle is in the fabric at the front of the marked line

7. Begin sewing the first part of the button hole; the column of small zig zag stitches on the left side. The fabric will move forwards instead of backwards. Stop sewing when the other end of the marked line is reached.

When sewing ensure the stitches run straight and follow alongside the marked line; this can be the trickiest part of sewing a button hole. The fabric will move slowly, do not be tempted to pull the fabric to speed it up, the stitches need to be close together, hence the fabric moving a small amount each time the needle raises.

8. With the needle raised, set the machine to sew the 2nd part of the button hole; the closing bar

9. Sew 4 stitches for the bar, forming the wider stitches that span the top of the button hole

10. With the needle raised, set the machine to sew the 3rd part of the button hole; the right column

11. Sew along the other side of the marked line, the fabric will move backwards. Follow alongside the marked line and don’t let the stitches overlap the 1st column

12. With the needle raised, set the machine to sew the 4th part of the button hole; the closing bar

13. Sew 4 stitches for the bar, forming the wider stitches that span the bottom of the button hole

14. With the needle raised, set the machine to sew the final, and easily forgotten, part of the button hole; lock stitch.

15. Sew 3 or 4 stitches to secure the thread ends then cast off.

16. Repeat for the other button holes, then reset the machine for normal sewing.

Opening the button hole

17. There are a number of ways to do this, with any method take care to avoid cutting through any stitches.

Before cutting a buttonhole place a button between the closing bars to check the button hole for size, if the buttonhole is too big/ small see the troubleshooting tips below.

- Fold the buttonhole in half lengthways and using small fabric or embroidery scissors make a small cut between the 2 columns of stitching. Unfold the button hole and cut up to, but not through, the closing bar at each end.

- Insert a seam ripper through the fabric between the 2 side columns and make a small hole. Using small fabric scissors cut between the 2 columns of stitching up to, but not through, the closing bar at each end. You can place a pin at the end of your button hole to ensure your seam ripper does not cut through your button hole stitches.

- TIP: Place a pin at either end of your button hole to ensure the seam ripper doesn’t cut your stitches

- Position a pin just below the top closing bar. Just above the bottom bar insert the point of a seam ripper and carefully cut between the columns with the ripper until the ripper blade meets the pin.

- Insert the point of the seam ripper close to the stitching of one closing bar and cut between the columns to the centre. Repeat from the other end of the button hole

Once the buttonhole is opened any loose threads can be trimmed

18. Test the button fits through the finished buttonhole.

Buttonhole troubleshooting

- Always practice buttonholes on a spare piece of the project fabric to check for adjustments

- Buttonholes are difficult to unpick but not impossible, ideally unpick a problem button hole before cutting it open. Though not impossible, it is harder to sew over an already cut button hole

- If a buttonhole is a little too big the closing bars could be extended inwards with a few more stitches. Set up the machine for a closing bar, line the buttonhole up under the needle and sew a few stitches, not forgetting to lockstitch start and end to secure. If a large adjustment is needed, add a few stitches to the top and bottom to even out the appearance, or consider unpicking and trying again.

- If a button hole is too small the easiest solution is to unpick and start again. Or the top closing bar can be unpicked, lock stitch overlapping the top stitches of the left column, extend the left column, sew a new closing bar, extend the right column overlapping the ends, then lockstitch

- If one column’s stitches are denser than the other, consult the manual. Many machines have a button hole balance adjustment. The balance needed can vary from fabric to fabric; a benefit of sewing a practice button hole for each project

- If the lines aren’t straight, practice by sewing along a drawn line. Go as slow as needed, occasionally lift the presser foot with the needle down to track progress

- If the column stitches are overlapping: Some machines will make a slightly wider column stitch depending on the position on the stitch width dial. If the width dial doesn’t ‘click’ into the buttonhole setting, turn it a little closer to 0 and sew another test button hole

Sew on the buttons

57. Check each button position mark lines up with the centre of the corresponding button hole

58. Sew the buttons on

How to sew quick and easy buttonholes: Video Tutorial

We hope you found this tutorial useful.

Let us know how you get along in the comments below!

Pin this for later!

Follow Plush Addict on social media and keep an eye out for more tutorials. Please tag us @PlushAddict on your fave social media channel… we love to see your makes!

A Guide To Haberdashery – A History and Definition

3.5 minute read

Haberdashery – it’s a great word, isn’t it? Ever wondered what it is? Or where such a wonderful word comes from?

You’re not the only one!

Read on to find out all things haberdashery. We’ll be going into detail and explaining all you need to know to become a seasoned haberdasher. You’ll feel confident going out and exploring the world of sewing accessories!

Boring Legal Bit: If you follow any tutorial or guidance found in this post, or on this blog, you agree to be bound by our disclaimer which can be viewed here

History of the word Haberdashery

Haberdashery is pronounced “ha-buh-da-shu-ree” and has a rich history. It’s such a great word! But where did it come into our language?

One of the first sightings of the word is seen in English poet Chaucer’s Canterbury Tales. Chaucer describes peddlers who sold buttons, needles & other sewing items. This dates the word back to at least the 14th century!

Haberdashery derives from “hapertas” that’s thought to have meant “small ware”, although others say it was used to describe a type of fabric.

The word has been around for centuries, nonetheless the true origins of it are still unknown today.

Often the word “haberdashery” is shortened to “habby” so if you hear that being banded around, you know what this abbreviation means!

UK & US Haberdashery Differences

Interestingly the word haberdashery has a different meaning with our friends across the pond in the US, instead, the word “notions” is used to describe haberdashery supplies!

Over in the US the word Haberdashery is instead a term used to describe a speciality accessory store for men selling hats, gloves & scarves.

But they also sell what we now know as haberdashery supplies in the UK – buttons, needles, threads and more!

As time passed US haberdasheries evolved to also tailor to women, but still focused on hats and accessories.

However here in the UK they became the go-to place for all sorts of sewing bits and bobs, more of a craft and sewing shop.

The world of sewing and sewing accessories has experienced a massive boost in interest recently partly due to the pandemic, lots of people turned to their hobbies to pass time and even more people discovered new hobbies!

The Great British Sewing Bee has also massively contributed to the expansion of sewing and haberdashery in Britain, we all love a good competition!

What supplies do you find in a haberdashery?

ALL the sewing things! In short it’s an all encompassing word describing is the small bits & bobs used in sewing projects. You could call them a seam-star’s sewing accessories.

Some common items are:

- Needles

- Thread

- Interfacing

- Fastenings

- Scissors

- Tape Measures

- Buttons

- Elastic

- Fabric Dye

- Zips

- Wadding

- Bias Binding

- Toy Stuffing

This list isn’t exhaustive – there’s literally hundreds of variations for each of these items – it’s pretty broad.

More often than not you can’t complete a sewing project without using some type of haberdashery! And over time your stash will increase (along with your need for habby storage & organisation 🤣)

Where can you buy haberdashery supplies?

Habby items are usually sold by fabric & sewing shops. A Google search for “haberdashery near me” will bring up all your local merchants, it’s a great way to support local small businesses!

And if there’s not one near to you then we’re here to help! Our online sewing superstore has a HUGE range of haberdashery items & we ship sewing supplies not only throughout the UK, but worldwide too.

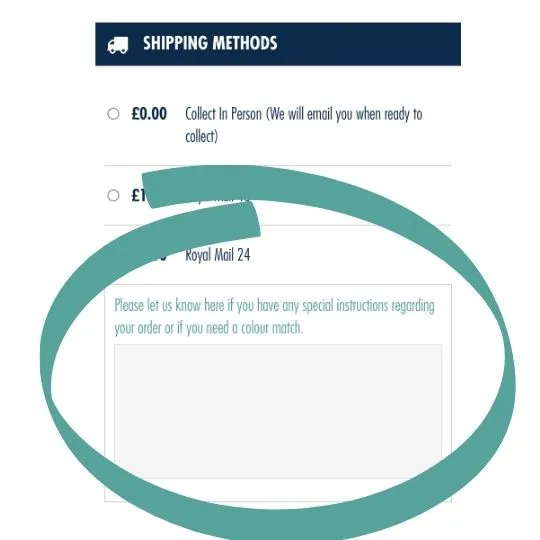

We know that sometimes buying sewing supplies online can be daunting. What if the colours don’t match?! Colours CAN be off when buying from a screen – we totally get this… There’s nothing more annoying than ordering a thread to match your fabric from screen, only to have it arrive and it’s totally off.

We have a service available as standard to eliminate any matchy matchy stress! We offer a free colour match service. Just order what you *think* matches then leave us a comment in the notes field at checkout asking us to check that your colours match. If they don’t – we’ll swap them for you – simples!

And if when your new haberdashery items arrive they’re not right, we also offer Free UK Returns!

About Us

Plush Addict is a local, family run business started by myself and Mr.Plush (Hubbydasherer) over 9 years ago. We’ve grown from a bedroom business selling cloth nappy supplies to having one of the best stocked haberdasheries in the country!

We stock a huge range of both fabric & haberdashery and we strive to be a one stop shop for your sewing projects.

We hope you found this insightful and learnt a little more about the history of haberdashery.

If you stumbled here looking for some sewing bits, head on over to our website to shop all things haberdashery and fabric!

Follow Plush Addict on social media and keep an eye out for more tutorials!